Home » News » Food Processing » Identify cross-contamination in cereals

Identify cross-contamination in cereals

Identify cross-contamination in cereals

Soy is a legume and today is one of the most cultivated food products in the world. Food allergens are those foods, or their ingredients, that are considered, in common use and by legislative, allergenic, that is, triggering immune-mediated reactions. Soy is one of the main allergens, along with milk, eggs, peanuts, wheat, fish (eg cod), crustaceans and nuts (eg hazelnuts, walnuts, almonds, pistachios, etc.).

The European Regulation n. 1169/2011 obliges manufacturers to declare on the label of their product the presence of substances that cause allergies or intolerances. The producers therefore have the right to take all appropriate measures to prevent the presence of allergens and inform the consumer adequately.

Figure 1. Presence of soy in durum wheat. Soy can be in the form of whole and halved grains, with and without peel.

Cross-contamination

World production of soya has grown by over 230% in 26 years, reaching 348 million tons in 2017.

The raw materials used in food processing are usually agricultural products, so it is not possible to totally exclude an accidental and fortuitous contamination of allergens, especially for soybeans if we consider the high volumes produced and handled. This contamination is called cross-contamination.

Currently no tools are available to verify that these allergens may have contaminated the raw material stored and delivered to the processing plants.

The danger of the presence of allergenic substances may be due to:

- crop rotation of fields with presence of legumes;

- cleaning of harvesting and selection machines;

- transport and storage;

- environmental factors (wind, rain, etc.);

- human activities (sampling, withdrawals, etc.).

Today it is only possible to introduce prevention measures to prevent cross-contamination. Such procedures require the introduction of best practices for the correct igenizzazione of storage centers and of the means which have transported the raw material.

It may contain traces of…

The most virtuous companies perform continuous analyzes within their production cycle and adopt high-tech machinery to exclude the presence of allergens in raw materials and verify their presence in the finished product.

These efforts, together with the fact that the European Regulation n. 1169/2011 does not indicate minimum thresholds of acceptability due to the presence of allergens, do not allow unequivocally escaping the presence of allergens in the finished product.

Therefore, most companies decide in a precautionary way to declare the possible presence of traces of allergens in the label of their products under the ingredients list, with the words “It may contain traces of…“.

All this could appear as a convenient choice; however, the application of food safety legislation is not excluded, which nevertheless requires the company to identify critical points within its production cycle, implementing measures to control the hazards detected.

Soy in wheat

Let’s analyze a typical example of cross-contamination in food processing: the presence of soy in wheat. The allergen fraction of soy is protein. Many soy allergy sufferers can tolerate refined soybean oils but do not tolerate the presence of soy in flours: it is therefore crucial to exclude their presence in the mill.

The presence of soy in wheat seems to be mainly linked to two elements:

- the transport, the grain is transported by sea in the hold of the cargo ships, which previously transported soy, so some bean of soy may have contaminated the grain;

- storage, the grain is stored in silos that previously housed the soybean and that have not been perfectly cleaned.

The most innovative optical sorters on the market today and aimed at cleaning grain are struggling to identify soy, because it has the same color of wheat (although the shape is completely different). In addition, the tools that analyze the shape of the grain perform an analysis so slow that it does not comply with the processing rate of a medium / large mill.

Finally: the cost of the instruments is high and difficult to access by companies.

It can be deduced that soy-free labeling of semolina / flour / pasta is, in fact, impossible for mills and pasta factories that process large quantities of raw material.

Figure 2. Comparison between soy and durum wheat. The two grains have a very similar color histogram and are hardly distinguishable from most of the cleaning systems currently on the market.

Medusa: the solution

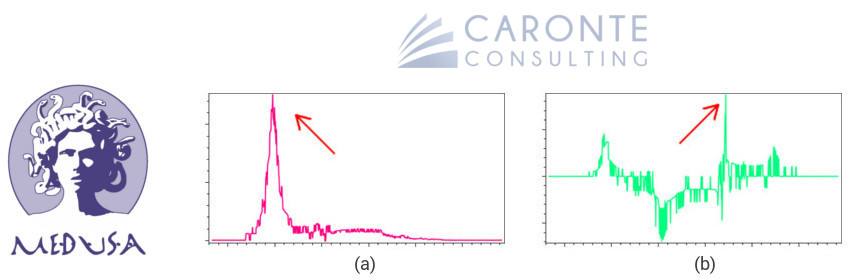

Through the experiments conducted with Hydra and Valery, Caronte Consulting has developed a hardware module that allows to identify allergenic elements, such as soy, sesame, etc. in cereals and grains in general.

This module is called Medusa and allows you to examine the presence of allergens online, both on the raw material, both on fractions and production waste. Some striking results are shown in Figure 3.

Medusa can be installed in conjunction with Hydra, managing to identify the presence of allergenic contaminants in fractions, in the finished product and in production waste.

Medusa can be installed together with Valery, managing to identify the presence of allergenic contaminants directly in the raw material.

Figure 3. Hydra graphs showing the presence of soy and sesame in durum wheat semolina. The Medusa hardware module highlights peaks, at certain frequencies, that identify the contamination of the semolina with soy protein (a) and sesame proteins (b).

Would you like to know more?

If Medusa intrigues you and you want to know more about how it works, you can contact us in several ways: choose the one you like best. We will be happy to give you all the infos you need, without binding you to any purchase.

Discover some of our products

Caronte Consulting designs and manufactures hardware and software systems in the field of Industry 4.0, equipped with sophisticated and effective Artificial Intelligence.

Our devices are tailor-made to the customer’s needs and allow you to completely automate industrial processes, optimizing production and creating savings in raw materials and energy consumption.