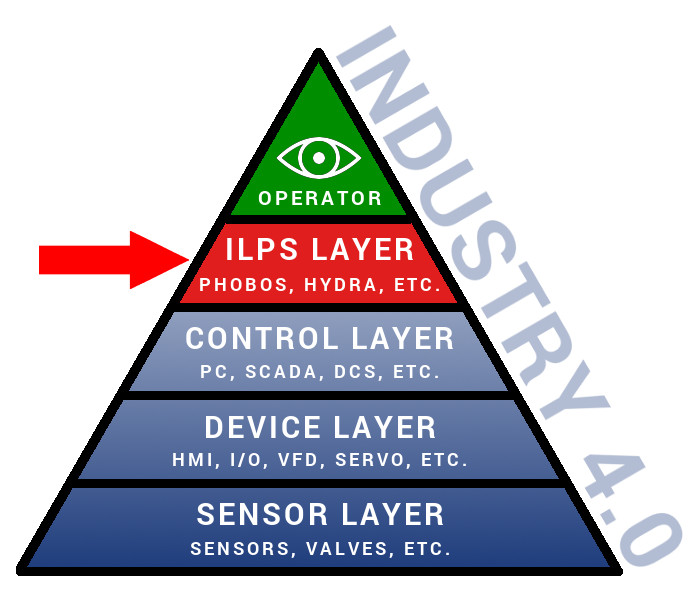

Figure 1. Pyramid of Industry 4.0 (CIM model).

Artificial intelligence

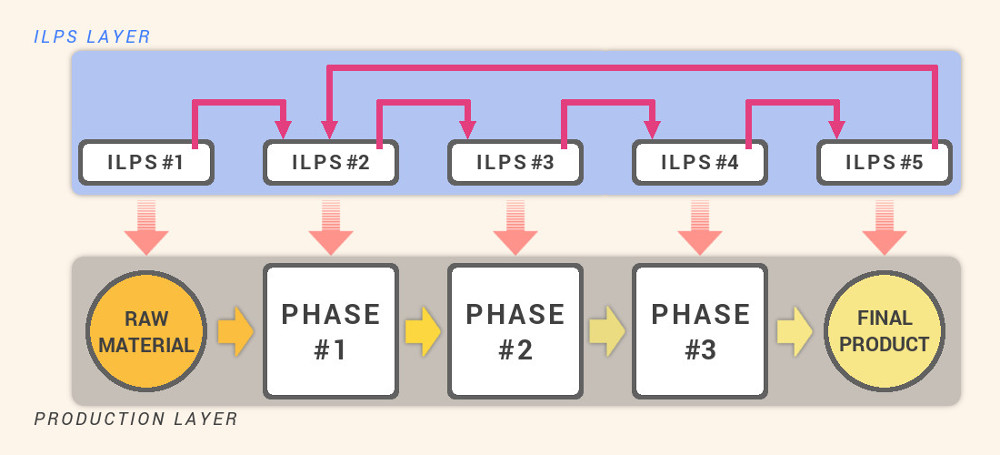

The ILPS identify in advance the drifts and, in real time, elaborate a solution and intervene modifying the machines setpoints. How do they do it? These devices have a hardware that allows to perform a large amount of operations per second, so they can be equipped with an artificial intelligence system that analyzes one or more process variables.

The artificial intelligence systems are mathematical models trained to recognize in advance possible drifts of the plant and to intervene.