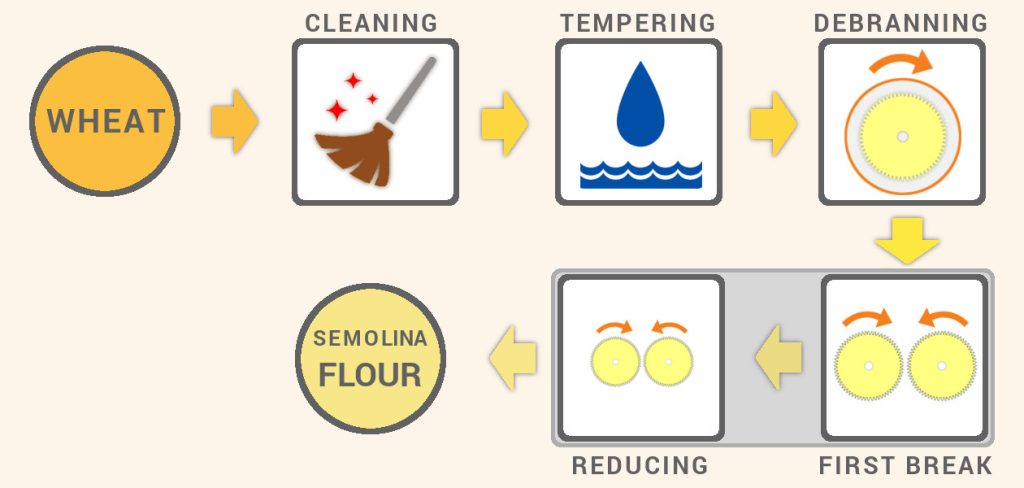

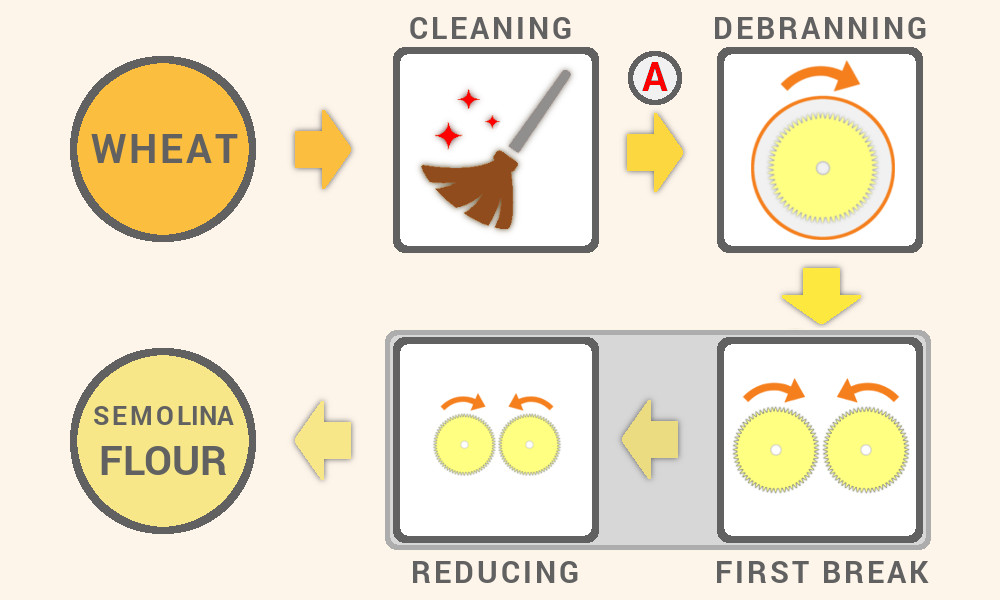

Figure 1. Generalized block diagram of a durum/soft wheat mill.

Tempering wheat

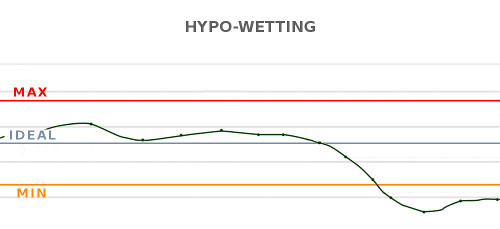

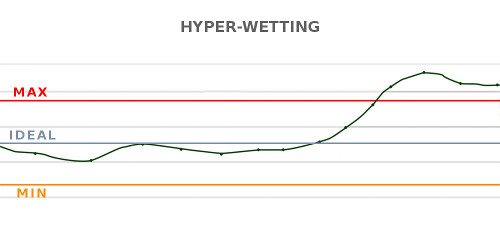

Tempering is carried out by adding water to the wheat.

There are several reasons why the miller wets the wheat:

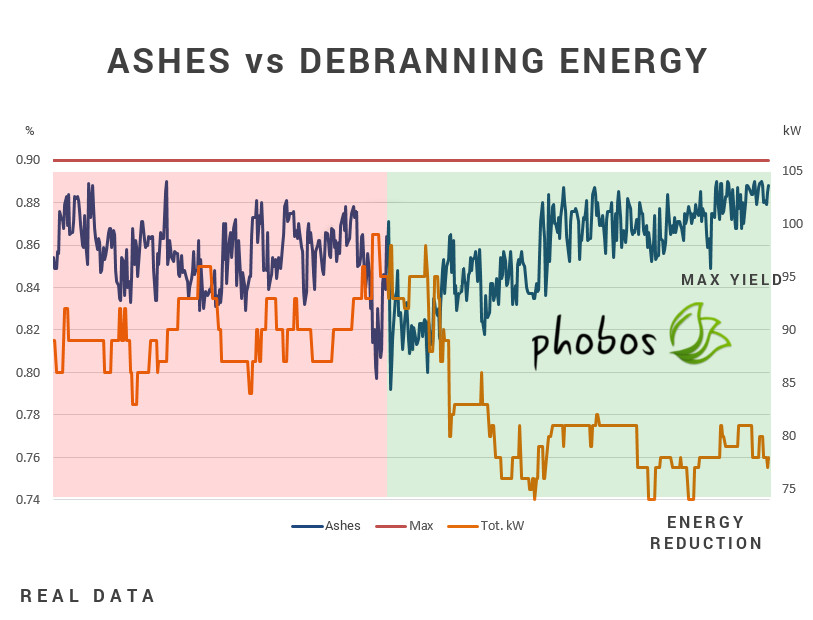

- moisten the bran, so that it comes out in an elastic way, avoiding as much as possible the contamination of the finished product so as not to excessively raise the ash content;

- facilitate the separation of the bran from the endosperm, obtaining the maximum yield;

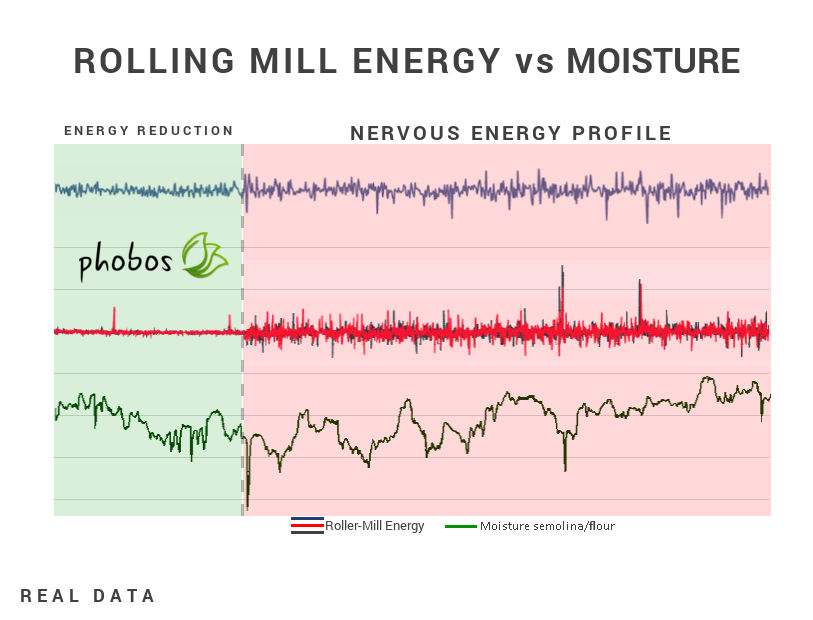

- to soften the endosperm, to reduce the energy consumption of the breaking mills;

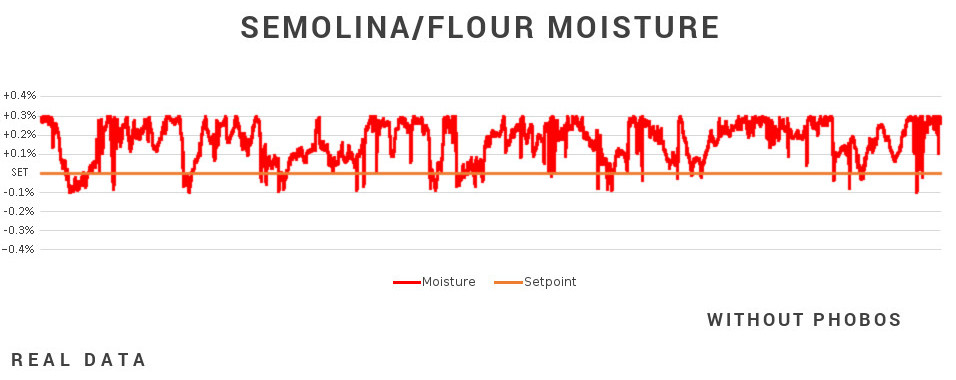

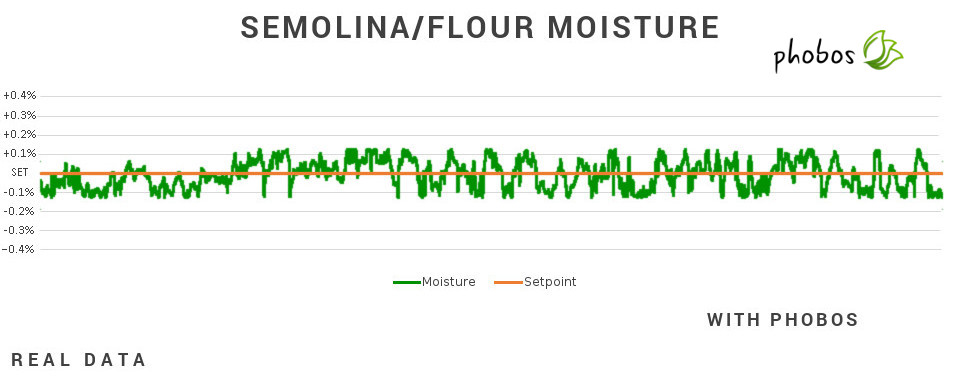

- guarantee a constant moisture value in the semolina/flour regardless of the climatic conditions.