PRODUCTS

Valery analyzes the raw material, determining its product characteristics

It is useful for raw material buyers, helping to perform a smart purchase by evaluating how the raw material will be processed by the plant. It can be used online, into the plant, to monitor the raw materials during their processing.

What is it

Valery is an extremely innovative device and represents all the courage and enthusiasm of Caronte Consulting.

It is a smart innovative device equipped with artificial vision capable of determining the product characteristics of the raw material. The device is designed to understand what is a “good raw material“, as an user would.

So far, the concept of “good raw material” was defined on the basis of the fact that this was fresh, genuine, carefully cultivated, which was free from pesticides or pathogens, which had important nutritional and organoleptic properties, etc.

With Valery this concept is renewed: the raw material is also chosen based on how this will be processed by the plant. For example, Valery will advise a buyer to not buy a raw material that has important nutritional properties if they will be discarded during processing! Also, Valery helps the buyer also determine what is the right price for the raw material you want to buy!

Valery can be used directly in the plant: the technologists can use it to validate the raw material upon his arrival, before being worked!

Hardware

Valery is a complex device and is built using only innovative and performing hardware. Caronte Consulting aims to make the energy consumption of Valery particularly low: it can be powered through a 12V battery for several hours, in fact it can be a portable device. Buyers can place Valery in their car’s trunk and use it to perform the analysis of the raw material they intend to buy.

All plastic supports inside are 3D printed so they can easily be customized or reprinted in case of breakages.

Valery is equipped with an extremely innovative and performing multispectral chamber, to which an innovative spectrophotometer can be combined.

Communication with the external world takes place through a Wi-Fi 2.4GHz IEEE 802.11 b/g/n/a-c connection, so cables for data connection are not required!

Software

The real heart of Valery is its smart software that can acquire a high amount of data on the monitored raw material. All these data are combined with each other in order to identify the product characteristics sought by the Customer.

Valery has a database of details on the raw material that establish when this is “good“. Valery executes quickly different sample analyzes, comparing the data obtained with its database, identifies the differences and returns two values:

- the amount of wastes that are in the sample;

- the maximum achievable yield.

Valery can identify soy in wheat

What does "wastes" mean for Valery?

With the term wastes Valery wants to express “what the plant will discharge during the whole processing of that sample”.

When you deal with so innovative devices it becomes a bit hard to explain its potential. Let’s take an example.

Suppose the buyer of a mill is buying wheat and gives Valery a sample of it. After a few seconds of analysis, Valery claims the following: “The amount of wastes in this sample is 19%, the yield will be 81%, the estimated price for this wheat is 295.50 €/ton” .

What does the 19% represent? It represents the sum between the wastes naturally present in the wheat (eg. damaged, sick or deformed grains, straw, pula, white belly, etc.) and what will throw away by the plant during processing (eg. bran, aleuronic layer, starch, etc.).

From this example you can understand that Valery can help the operator to buy that raw material that has particular nutritional features, and to be easily worked by your plant! Valery also suggests the right price to pay for that kind of raw material!

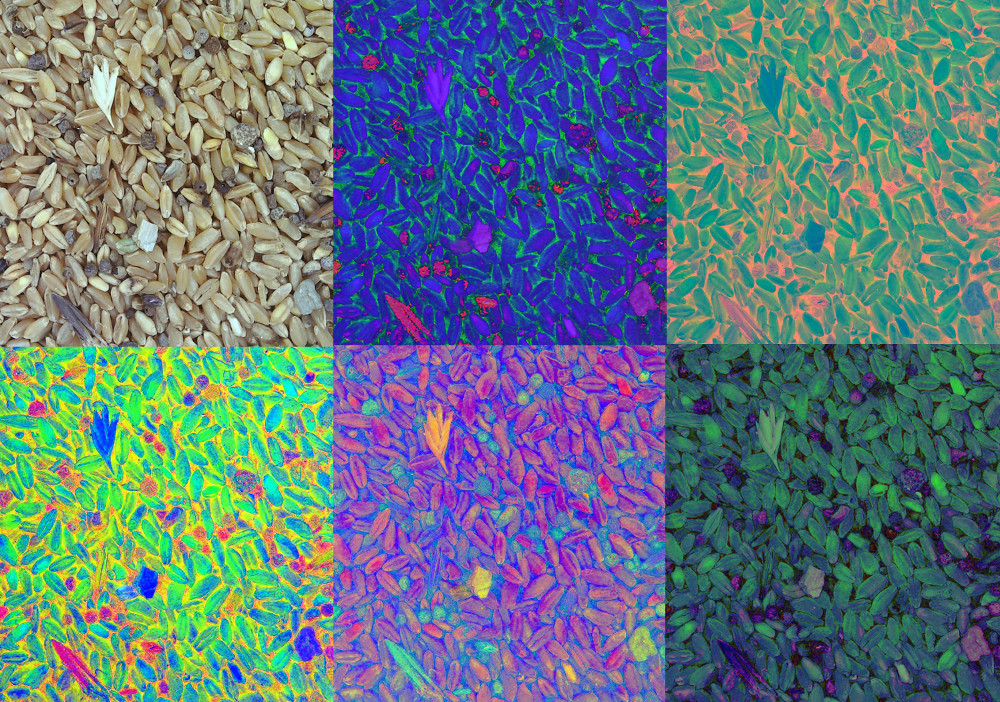

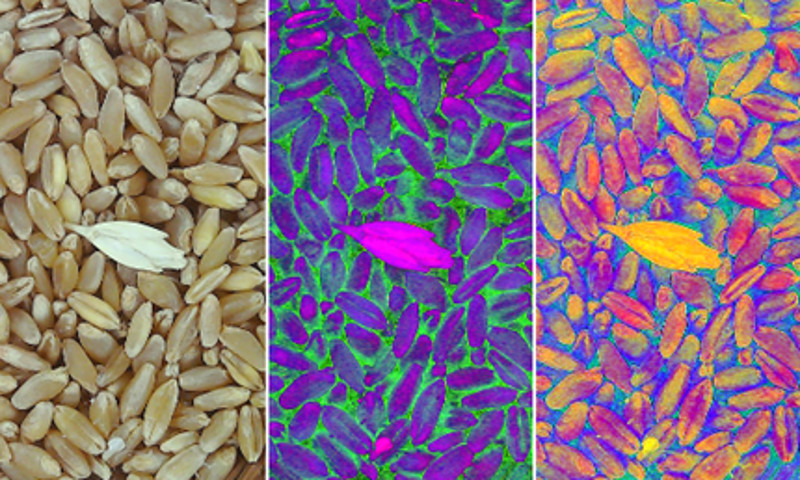

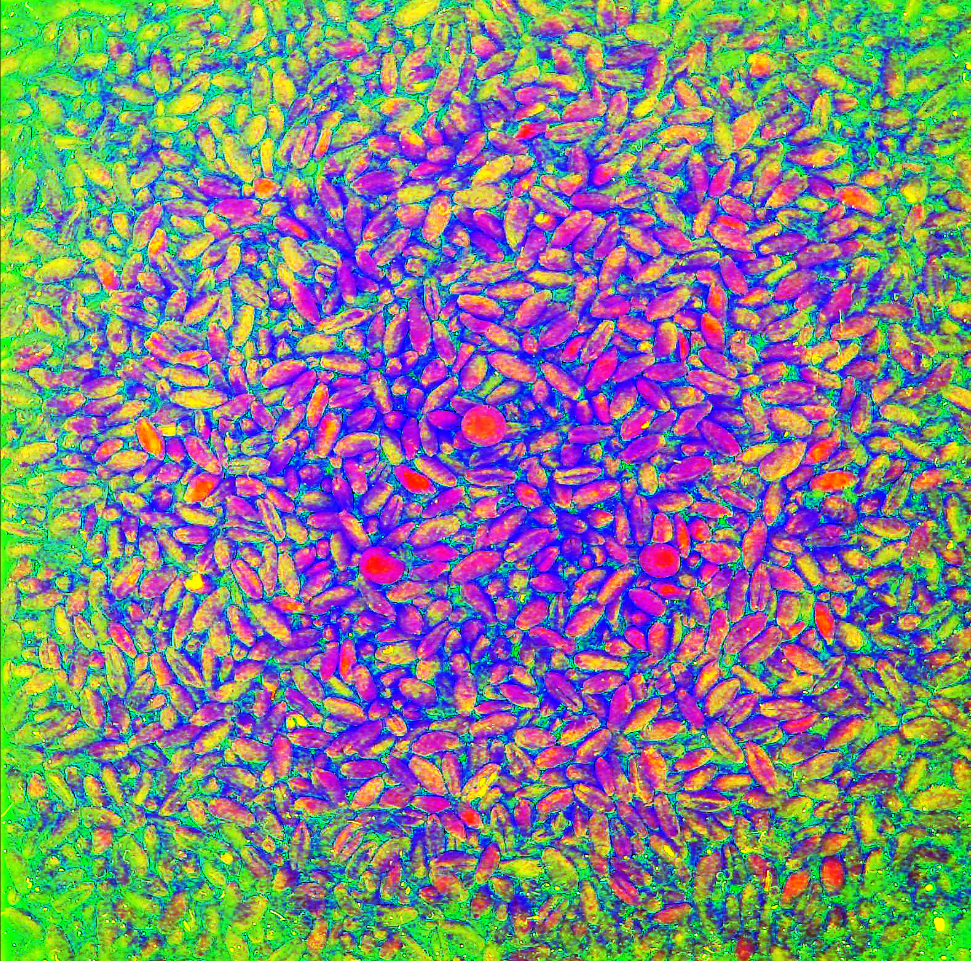

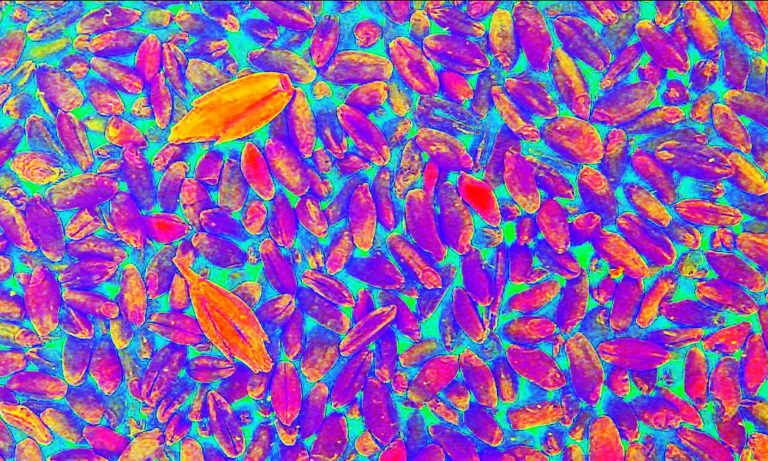

Image segmentation & Pattern recognition

Valery’s software is extremely smart and complex. It is equipped with sophisticated mathematical and image analysis tools that identify details int the raw material that can be of strong interest for the Customer.

Among these tools there are image segmentation techniques and pattern recognition. For example, with Valery you can identify the type of disease that affects every single grain in the wheat.

With Valery it is possible to identify allergenic elements, such as the presence of soy in wheat! This feature is not to be underestimated, because it can help the Customer to produce a free soy product, even succeeding in identifying very small fragments of soy.

Discover the other systems that optimize the industrial process

Our devices can be used in all types of industry, from the raw material to the finished product.