PRODUCTS

Phobos is a device that avoids drifts in the plant as an user would do

Phobos finds the relationships between process and environmental variables, identifying the corrections to be applied to the machines, creating an automatic and intelligent process

What is it

Phobos is a device that aims to avoid the drifts of the production process. It is designed to monitor all the environmental and process variables made available to it, find relationships between them and identify corrections to be applied to the machines, as an user would do.

It is equipped with intelligent software, built with Open Source tools, through which it learns to interpret the trend of the production process, identifying any drifts. Its smart layer does not end there, in fact Phobos also interprets the result of its own operations: if it has made a mistake, it will avoid making it again in the future!

How it works

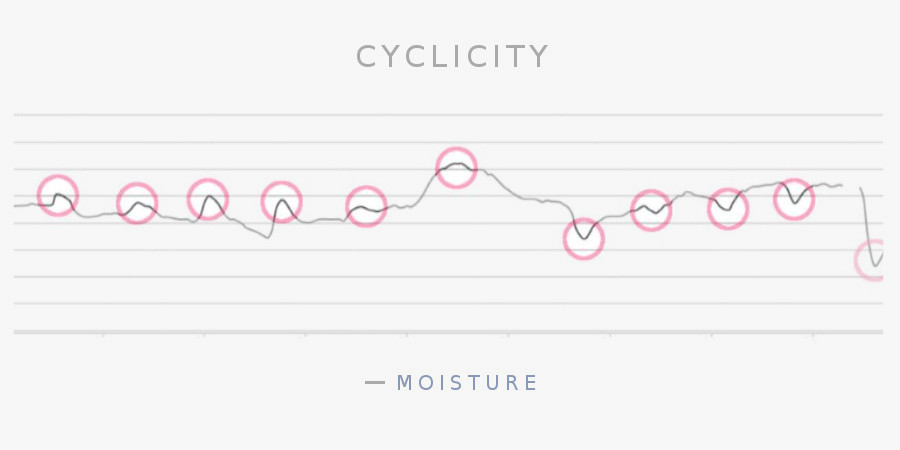

Phobos comes into action after a short start-up period during which it learns to identify the trends of the variables and the relative responses of the users, updating its deductions and the mathematical formulas that shape the system. During this period, the tool also learns to understand what is the best time interval with which to monitor trends and impose corrections.

Phobos can process many variables at the same time. In the grinding sector, for example, it has been applied with total success through a configuration of up to 26 variables (mixed, environmental and process). For example, in the mill it is able to identify the variables that directly affect the humidity in the flour / semolina.

Fundamental in mills

Phobos regulates the wetting phase of the wheat by providing the correct water dosage based on the environmental and plant conditions.

To learn more, you can read the in-depth analysis Smart wetting of wheat.

Up to now, the wetting of the grain has been regulated by devices that dose the water based on the moisture level of the grain and its desired moisture level at the end of this phase. Despite this automatic adjustment, there is always a moisture change in the moisture of the flour/semolina! Why? The reasons can be many: a dehuller that stops, a new adjustment of the rolling mills, a dirty water filter, an uncalibrated dispenser, etc. Phobos analyzes the variables and immediately detects if something happens that negatively affects the wetting, alerting the user and correcting the wetting in real time!

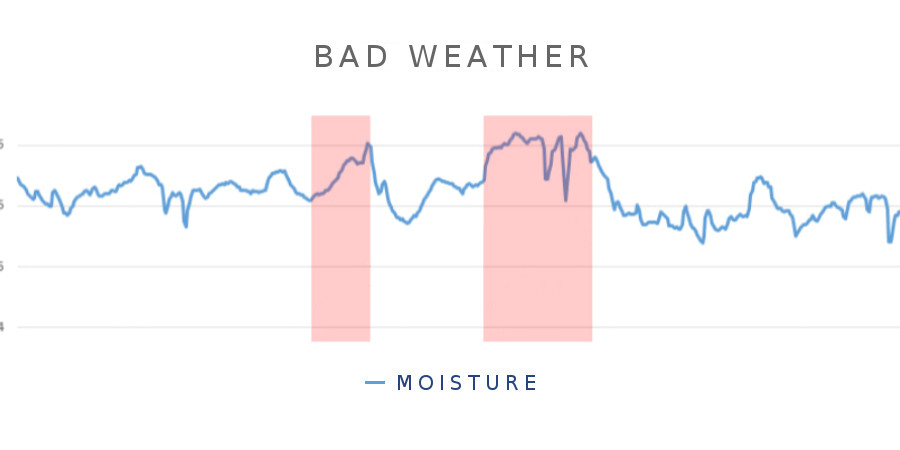

Among the many variables that Phobos manages to examine, there are also the weather forecasts! On the basis of these and other variables that affect the plant, Phobos is able to continuously correct the water dosage during the wetting phase, managing to obtain a constant moisture level of the semolina. Phobos, therefore, transforms a process based solely on the subjective choices of the user into a truly automatic and smart process.

Hardware

Phobos hardware is innovative and is based on both a microcontroller and a microprocessor. The hardware is an ILPS, Innovative Low Power Solution, and has a very low power consumption.

Phobos can be considered as a real computer combined with a microPLC. With Phobos it is possible to communicate with other PLCs, acquire information from other sensors, communicate with PCs, SCADA systems, etc.

The heart of Phobos is its tailor made software, designed on the needs of the Customer: no two devices are alike in the world!

Sensors

Nowadays there are many sensors and these can be used to improve and to strengthen the brain of Phobos!

Phobos can be configured with both analog and digital sensors. The configurations that can be created are infinite and depend only on the parameters that the Customer requires: temperature, humidity, magnetic fields, voltage, current, vibrations, pH, conductivity, etc.

Software

The programming of the device follows this philosophy: Phobos is managed by a GNU/Linux operating system and is programmed with Free Software and Open Source software.

Phobos is equipped with a smart software layer, realized in pure Python code, able to understand the state of the process and to manage directly the setpoints of the machines.

Packaging and maintenance

It is possible to allocate Phobos in a customized package, that shows the Customer’s logo, or it can be mounted on a DIN bar, in an IP65 box, etc.

Phobos has CE certification and it is a Made in Italy device. Most of its internal (and some external) plastic components are 3D printed.

The Customer is also given a PC and a monitor on which it is possible to view the progress of the variables, decisions and manage the device.

For the first year, Phobos maintenance is completely free. Much of the routine maintenance is carried out remotely; this is possible thanks to software created by us specifically for the management of interventions also on the other side of the world! These protection software are part of the Phobos equipment and in general, of the Caronte Consulting brand tools.

Communication

Phobos can communicate with the world through the use of various protocols: Ethernet (IEEE 802.3), Wi-Fi b/g/n/a-c, CanBus, ProfiBus, ModBus, etc. It can communicate with PLCs, SCADA, MES and SAP systems.

Last but not least, Phobos can be interfaced with an app specially created for Android smartphones and tablets!

Discover the other devices that optimize the industrial process

Our devices can be used in all types of industry, from the raw material to the product.